Corrosion Monitoring System (CMS)

The Corrosion Monitoring System (CMS) is a permanent sensor designed for continuous, real-time monitoring of corrosion rate and corrosion potential. It provides accurate, real-world data to support predictive maintenance, optimize inspection planning, and extend the lifetime of steel assets.

Ideal for hard-to-access or off-grid locations, CMS offers a reliable solution for long-term corrosion monitoring in harsh environments.

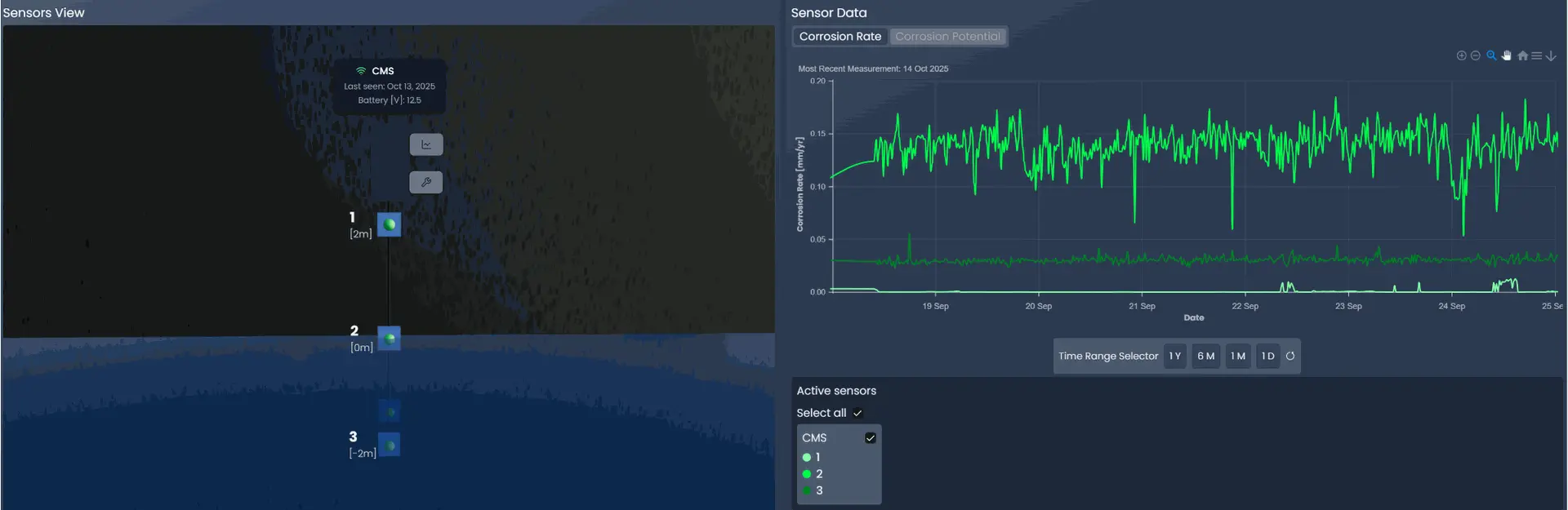

CMS sensors installed across above-water, splash, and submerged zones for full corrosion coverage.

The CMS enables you to:

- Measure corrosion rate and corrosion potential using Linear Polarization Resistance (LPR).

- Monitor corrosion activity continuously and automatically.

- Access real-time data remotely through a secure dashboard.

- Integrate corrosion data into lifetime prediction models and maintenance planning.

- Reduce maintenance costs and improve asset reliability.

Key Features

Real-Time Monitoring

Continuous, automated corrosion measurements with high accuracy.

Remote Access

Access live corrosion data anytime through a secure online dashboard.

Predictive Maintenance Support

Data enhances lifetime modeling and helps optimize maintenance schedules.

Scalable Design

Adaptable for multiple monitoring points or large structures.

Robust & Reliable

Built for long-term use in harsh, offshore, or industrial environments.

Easy Integration

Compatible with existing monitoring systems for seamless setup.

CMS Dashboard

The CMS dashboard displays real-time data on corrosion rate and corrosion potential, giving a clear overview of asset condition. The results below show distinct differences in sensor responses depending on their location — whether above water, in the splash zone, or underwater.

Ready to monitor corrosion in real time?

Contact us to learn how CMS can enhance your corrosion management strategy.