CQM for Jetties

Case Study 1: Maintenance Planning Through CQM

As part of a maintenance optimization program for aging offshore jetties in the Netherlands, the asset owner used CQM to assess coating conditions and guide maintenance decisions.

Challenge

Frequent, costly maintenance and downtime caused by uncertainty in coating condition.

Figure 1: The support beams.

Solution

C-Cube performed over 200 CQM measurements across five jetties, covering 80% of all jetty foundations. Measurements at key structural points captured variations in stress and environmental exposure, allowing accurate coating performance assessment.

Results

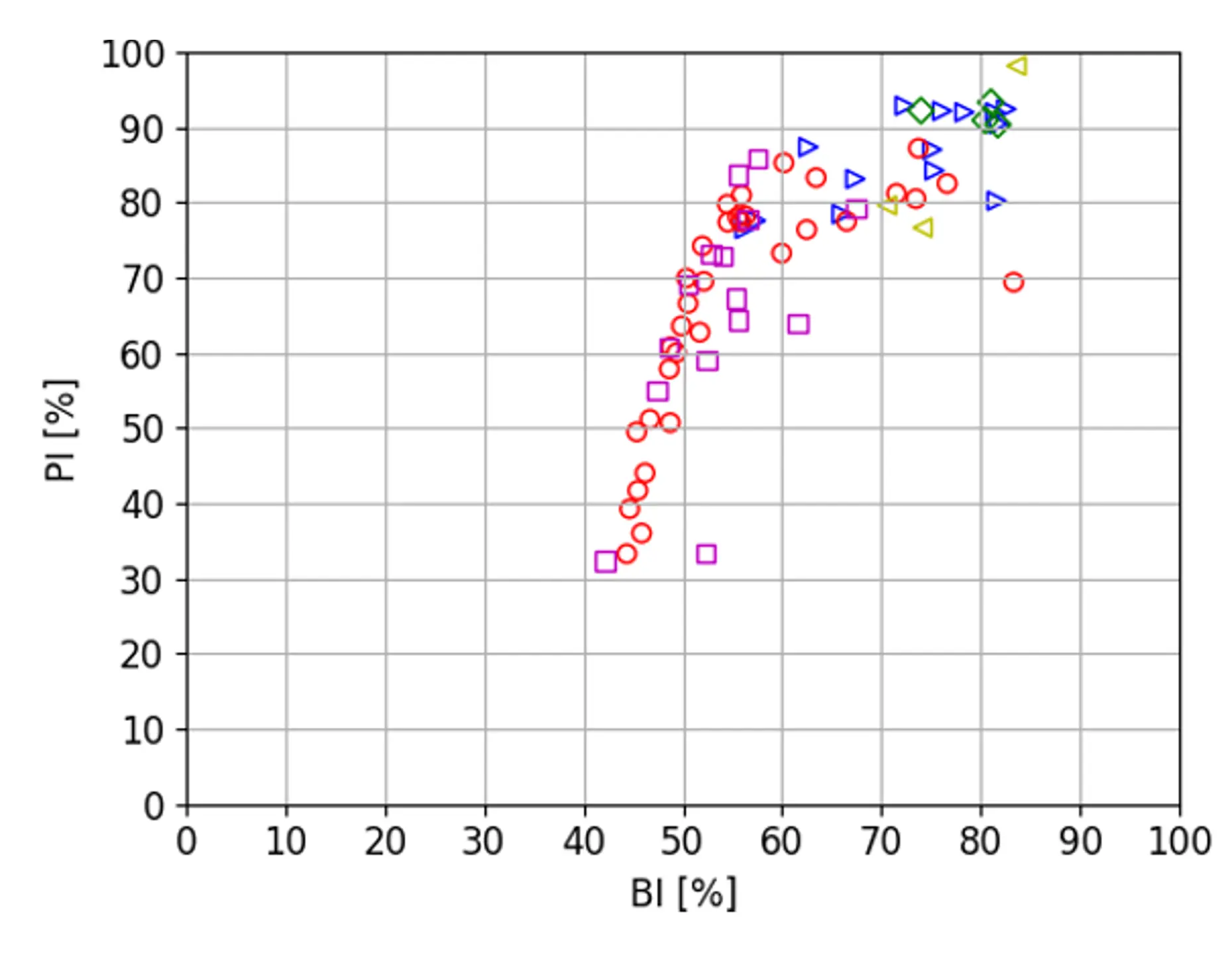

Using the data, the owner could segment foundations by corrosion risk and plan targeted maintenance.

- High-risk areas were treated immediately

- Low-risk areas were scheduled for future maintenance

- Localized repairs replaced full-surface treatments

Figure 2: Degradation model; each dot represents an individual measurement of the jetty.

Impact

✅ Avoided two weeks of downtime by eliminating blasting

✅ Optimized recoating (3-week savings) by focusing on critical zones

✅ Removed the need for cofferdam construction

✅ Bundled work across five jetties for efficient logistics

This data-driven approach resulted in significant cost savings, reduced downtime, and improved resource planning — proving the value of predictive coating assessment.

Case Study 2: Coating Quality Comparison Between Jetty Sections

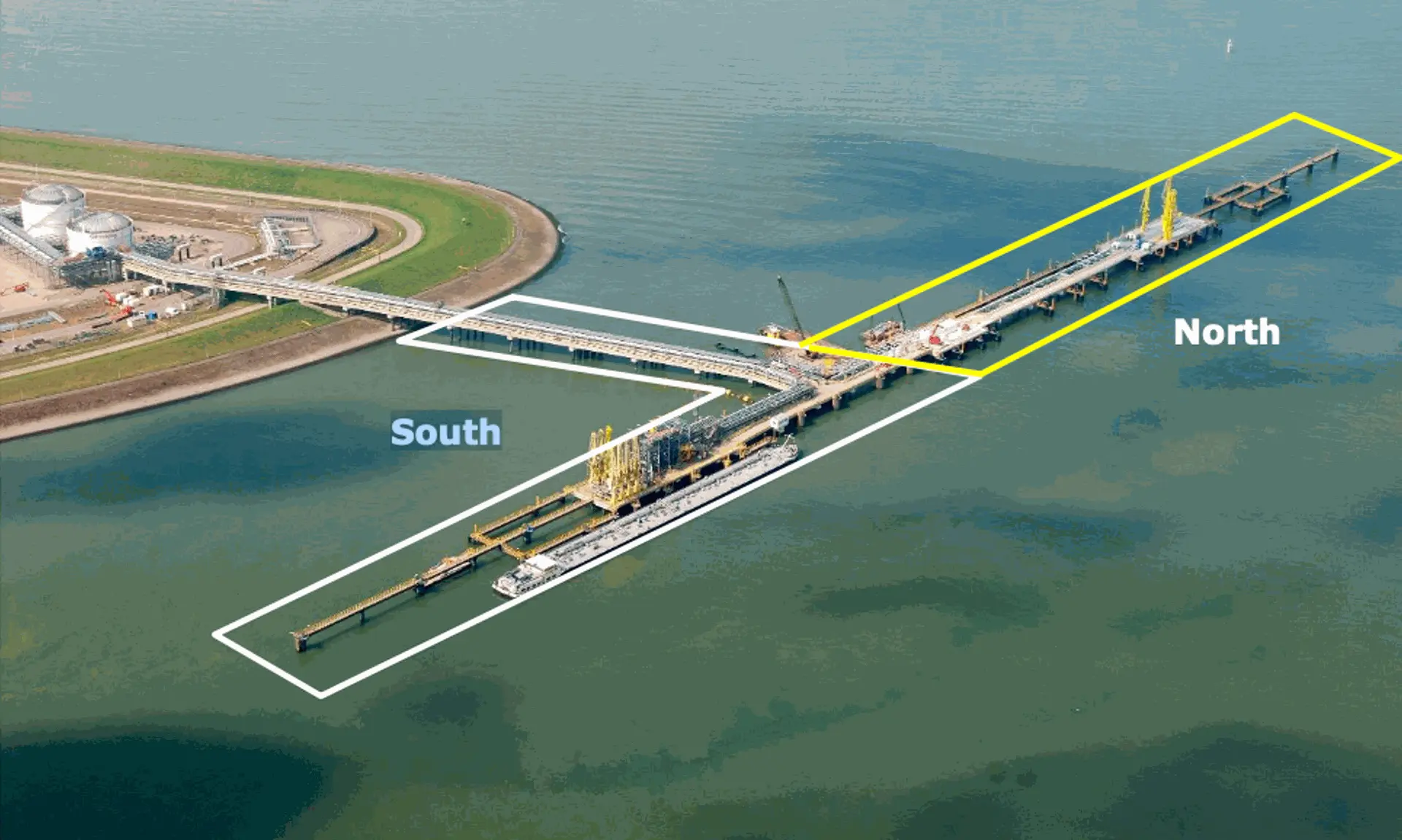

To support a condition-based maintenance strategy, an asset owner used CQM to evaluate the protective coatings on a jetty structure after 20 years of service.

Challenge

Both the north and south jetty sections were coated in 2004 using the same system but applied by different contractors. After two decades, the owner needed objective data to assess coating performance and verify application quality.

Figure 1: Jetty structure.

Solution

Over 200 CQM measurements were conducted across key structural components — including fender piles, support piles, horizontal support beams, head berthing piles, and mooring piles — on both sides of the jetty. The measurements quantified coating barrier properties, providing clear, data-driven insights into coating condition.

Results

The CQM measurements revealed:

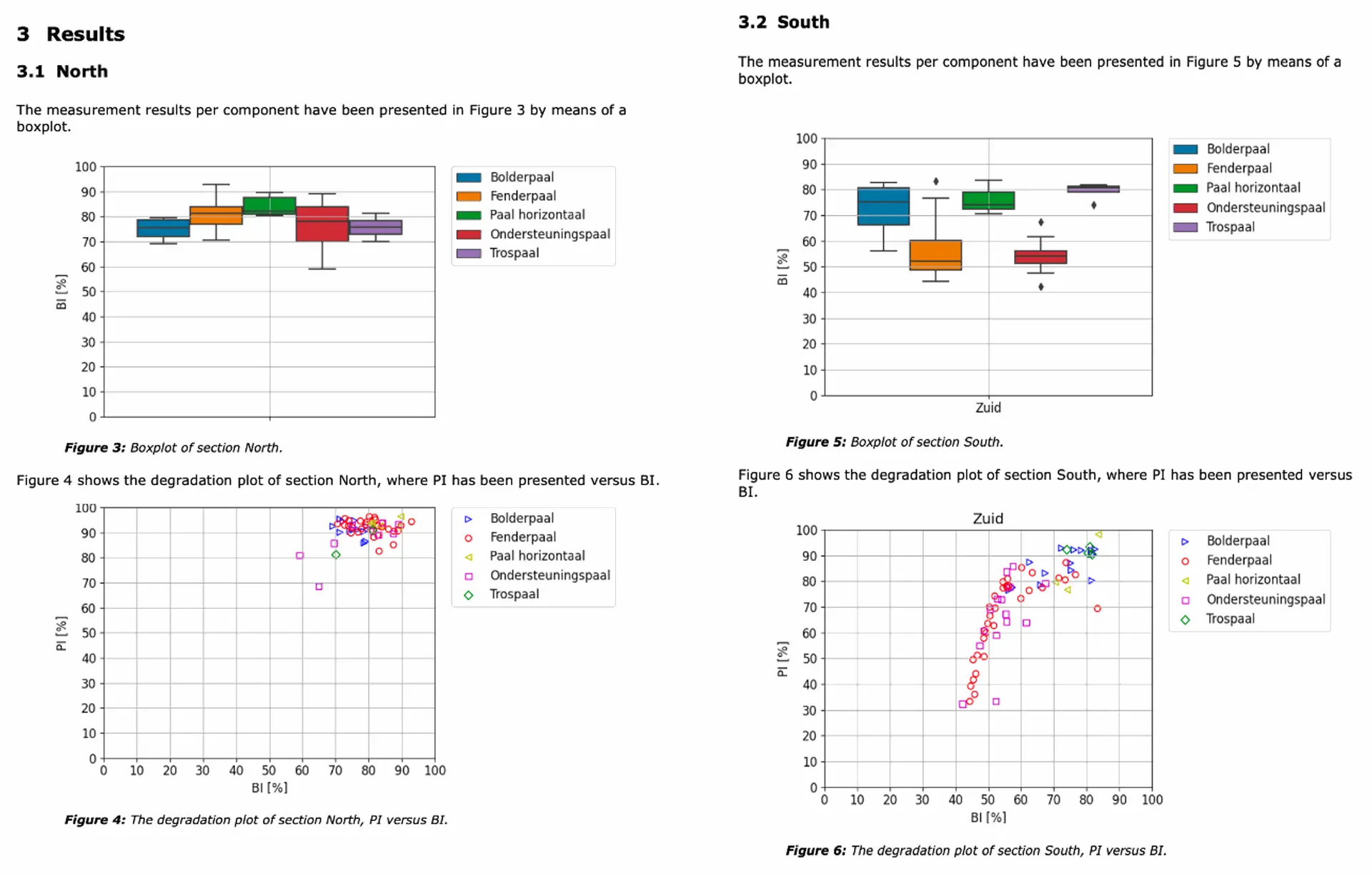

- North section: consistently high barrier properties and uniform coating quality

- South section: variable impedance values, indicating inconsistent surface preparation or coating appliation

Figure 2: North and South jetty results.

Impact

✅ Provided evidence for a formal claim against the underperforming contractor

✅ Enabled the asset owner to avoid unnecessary recoating on well-performing areas

✅ Reduced maintenance costs by 40–60%

✅ Supported lifetime extension and optimized maintenance planning

This case demonstrates how CQM empowers asset owners with quantifiable coating insights — useful not only for predictive maintenance but also for quality assurance and contractual verification.